Types of filters and their sizing

Swimming pool installations are in many cases part of the calculation and design of the plumbing, sanitation and electrical elements.

Within the principle diagrams of the operation of the swimming pools is the water purification and renewal cycle through filtering. That is why the question always arises as to what type of filtration to choose and what size is chosen for these filters.

There are various types of filters whose choice will depend on the level of filtration demand, replacement time, economic costs or energy consumption.

1. Sand filtration

Sand filters are the most used today due to their cost and level of maintenance. As the name suggests, the water is filtered through pressed sand, preventing impurities from returning to the pool in the recirculation cycle. In addition, they can be self-cleaning if we reverse the filtration cycle, expelling all adhered dirt.

Depending on the volume of the pool, we will choose a larger or smaller filter, and on certain occasions, for large volume pools, several filters placed in parallel may be available.

Within the sand categories, there is a wide product range:

- Silex Sand. Porous material made of flint that must be changed every 4 years.

- Zeolite. Formed by arid stones with high filtration capacities with capacities 3-4 times greater than sand.

- Filter glass. Environmentally friendly made from recycled glass with superior performance than Silex or Zeolite sand. It does not require changing, making it a filter for life.

Mainly, sand filters are used for private pools in single-family or multi-family homes.

2. Filtration by cartridge filters

Cartridge filters are designed to be interchangeable elements, just like we do with a vacuum cleaner. It requires a greater attention to maintenance and cleaning, since it is necessary to clean them weekly and replace them annually. Despite this, the operation is quite simple and very economical.

Mainly, cartridge filters are used for small removable or inflatable pools, even in fountains and ponds.

3. Filtration by diatoms

It is a high-cost filtration, but at the same time very effective. using fossilized microorganisms as filtration agents. Its operation is similar to that of sand, but instead of sand it uses diatom powder, that is, crushed shells and marine debris.

Unlike sand filters, they provide greater effectiveness and clarity in the water.

They are filters that require more maintenance, and their replacements are the most expensive.

4. Filter sizing

As a starting point, it is necessary to know the volume of the pool glass.

Likewise, know the use of the pool to know the minimum number of daily renewals to filter.

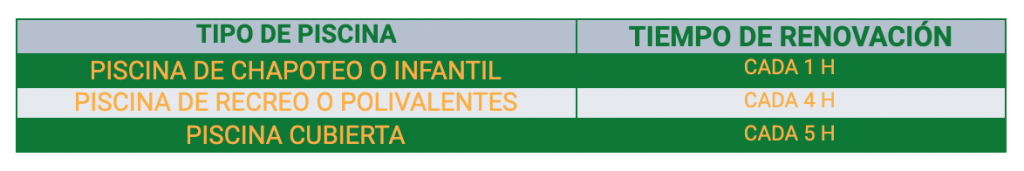

For reference, the hourly renewals imposed by the Andalusian Government according to RD 23/1999:

As a general rule, never exceed the renewal value for every 8 hours.

Once these conditions are met, we can now know the recirculation flow rate, both for the pumps and the capacity that the filters must support.

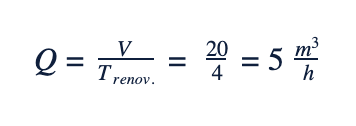

For example, if we have a 20 m3 recreational pool, the required flow will be:

Knowing the flow rate, we must assume the filtration speed supported by the filters. This speed indicates the amount of water flow that circulates through the filter for each m² of its surface (m³/h/m²).

The recommended value for Optimize the quality of filtration in a filter It depends on the filter material, but it is between 30 m³/h/m² and never above 50 m³/h/m².

As a middle point, it is a good value to estimate a filtration speed of 40 m³/h/m².

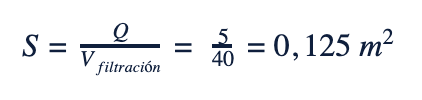

Continuing with the example, the filter surface should be the following:

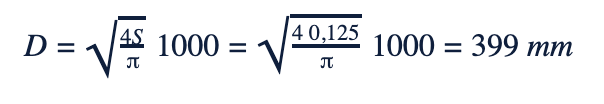

With the filter being circular and transforming it into mm we will obtain the Ø of the filter.

Therefore we must choose, at least, a filter that supports 5 m³/h flow and 399 mm Ø, so a Ø450 mm sand filter would be sufficient.

Post prepared by our expert teacher in Software Cype and BIM methodology in the EIP International Business School, Sebastian Fernandez Cano, Technical Director aBIMa Engineering.