In the materials management processes within an ERP system such as SAP, the purchase valuesThey represent a set of key parameters that allow you to control and automate different aspects of the purchasing cycle.

These purchasing values, which are configured in the material master within the purchasing tab, include data such as dunning days, tolerances, shipping rules, and automatic supplier reminders. Proper configuration is essential to ensure an efficient purchasing flow aligned with the organization's needs.

Purchasing Values Settings in SAP

When configuring a new material in our material master, we have settings in the purchasing tab that we can assign to them to determine the purchasing values.

These values can be assigned and configured and we can change them according to our needs.

The values we have assigned will be moved through the different documents that are created.

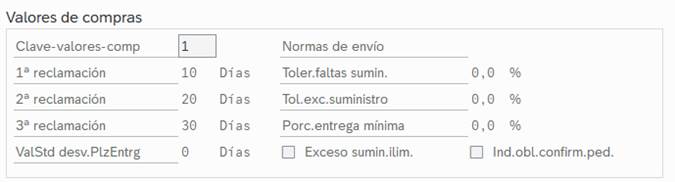

To view this configuration by default, we will access the purchasing tab of the material master:

Each of the values we assign will be marked with a key, which is parameterizable and we can assign different weights to it.

Key that defines the claim days and tolerance limits, as well as the shipping rules and the indicator for obligatory order confirmation of the material for Purchasing.

If you have selected a key purchase values, the system fills in the fields with the values stored in Purchasing Customizing.

In the purchasing documents, this data is proposed by the information record system or – if it does not exist – by the material master record.

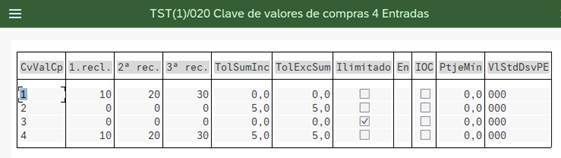

In our example we have these values marked:

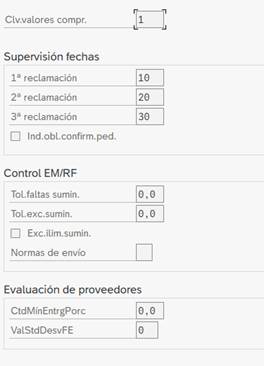

If we subsequently connect our system to supplier systems, automatically, if those days of complaint have passed, an email is sent or the system that we have parameterized, with a text that we have selected, to the supplier itself to remind them that "x" time has passed since the order was placed and it has not arrived or shipped, etc.

- Number of days for the first claim

Number of days indicating the time interval within which the supplier must be requested or reminded. A negative number of days means the supplier must receive a request or reminder n days before the delivery date (e.g., delivery date or bid submission deadline).

A positive number of days means that a claim or reminder must be submitted n days after a delayed delivery date.

- Standard value of delivery time deviation

Relativization value.

Value in days that specifies how many days of deviation from the planned delivery time should be taken as 100% of deviation.

If you enter a value, the system evaluates the absolute deviation in days between the planned delivery date and the actual goods receipt for all materials equally.

For this purpose, the actual (absolute) deviation in days is converted into a relative one and set in relation to the normalization value/relativization value.

If you have not set the 'Material MinInQuantity/StandardDeviation' indicator, this value is used; that is, in cases where no value from the material master record (purchasing value key) is to be used, or if the corresponding value is not maintained in the material master.

If you do not make any entries, the system calculates the value based on the order date and the statistically relevant delivery date for the scheduling agreements and the binding period.

If you do not update the minimum delivery quantity, each goods receipt (regardless of the delivery quantity) will be included in the notes calculation.

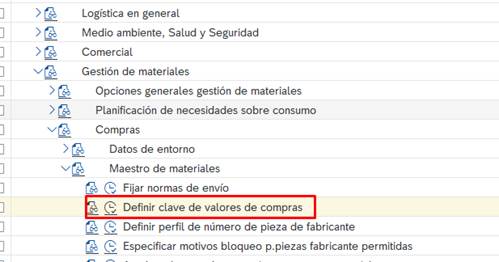

Parameterization of values

We access the SPRO transaction and verify in the Materials Management section, the Define purchasing value keys section.

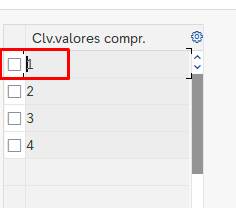

Once inside, we have the SAP standards, and if we click on one of them, we access the table shown in the Material Master.

We select 1, for example, and see these values entered. If we modify them and go to the material master, we see that they are updated according to the key.

With this configuration, we have more automatic control over the orders placed, and if there are no deliveries in reference to the order, we can notify the supplier that we have not received anything in our organization.

In short, purchasing values allow you to define clear and automated rules for order management, facilitating delivery tracking and communication with suppliers. Thanks to this parameterization, companies can optimize their supply chain, reduce errors, and improve operational efficiency by having greater control over the timing and conditions of their purchases.