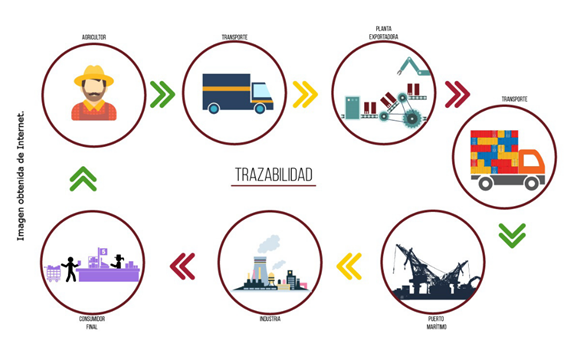

Understand the traceability It's like following a trail from your dining room table to the factory where a product originated, or from the electronic device in your hand to its place of manufacture.

This concept is fundamental in our daily lives, and in the logistics field, it becomes even more vital.

When someone asks me what SAP is and how it works in logistics, I usually use a simple example: Imagine you can take a product from the supermarket and, thanks to technology, a farmer or flour manufacturer knows when to produce more to maintain stock.

But what does it really mean? traceability?

Product traceability is the monitoring of a product's journey from its origin to its final destination. With this information, we can track where it was manufactured, where it was grown, when it was shipped, when it was produced, and many other details. This helps us detect problems such as defective parts in vehicle manufacturing or contaminated batches in the food industry, and allows us to take measures to prevent them.

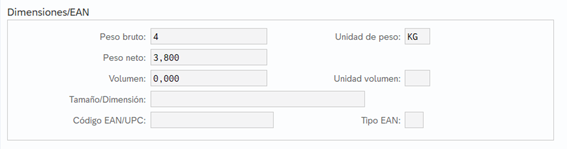

In SAP, we have several identifiers to uniquely track products. These include: DUN14 codes and the EAN codes, similar to barcodes. These identifiers play a crucial role in inventory and logistics management in SAP.

On the main tab of Base Data 1 in the material master, you'll find the EAN section. Here, you can specify the code type you want to use, and it will be automatically coded. This section is mandatory for any material master view and allows you to establish a unique identifier for each product in the system.

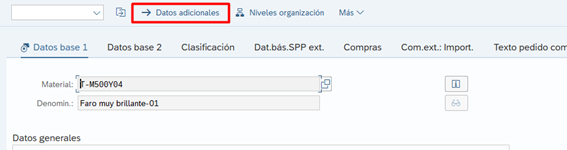

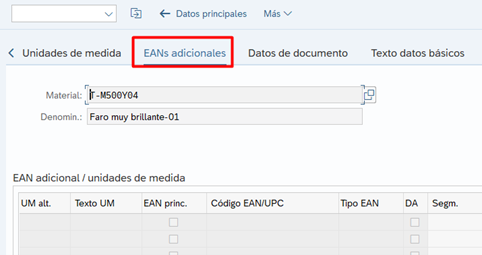

To access these additional EANs, simply go to the main Additional Data tab in the material master. Here we can record and manage the different codes associated with the same product, ensuring that each variant is correctly identified and tracked in the system.

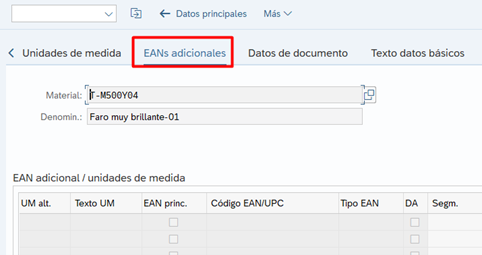

To manage other material codes that may change depending on dates or classifications, we use additional EANs. These additional codes allow us to maintain traceability and efficient product management in the SAP system.

In this section of the window, you can easily access the additional EANs associated with the material. This will allow you to have a complete and accurate identification of the product, as each variant or classification will be clearly identified.

In SAP downstream tables, product traceability can be verified by recording the dates of each movement in the production and distribution flow. This information enables detailed and automated tracking of the product throughout its lifecycle.

In SAP downstream tables, product traceability can be verified by recording the dates of each movement in the production and distribution flow. This information enables detailed and automated tracking of the product throughout its lifecycle.

Let's suppose we have a product that we purchased and manufactured in our company. Thanks to the SAP system, we can access crucial information, such as the product's supplier, the customer who purchased it, the processes it has gone through, the Incoterms applied, the storage centers it has passed through, and even the countries it has traveled to.

This detailed monitoring provides us with valuable data for future decision-making. We can analyze trends, identify areas for improvement in the supply chain, and anticipate production or distribution needs.

Let's Explore the Different Types of Traceability

Process Traceability: This type of traceability focuses on data obtained during the processing of raw materials in the industry. For example, when we convert flour into pasta, we need to know the ingredients used, the exact quantities, the processes it underwent, and the final result obtained.

Upward Traceability: Here we delve into the origin of a raw material with a minute level of detail. It's not just about knowing the product's provenance, but also about understanding the processes performed by the supplier, the manufacturing date, the registration, or the associated batch.

Downward Traceability: This type of traceability covers the logistics process from the manufacturing plant to final delivery to the customer. Monitoring each stage of transportation is essential to ensure quality and customer satisfaction. We can track the date the goods left the manufacturing plant, the quantities shipped, customer addresses, and the condition in which they were delivered.

Conclusion

Product traceability is essential for improving its quality. It allows us to identify errors and problems at any stage of the process and take corrective action. This not only guarantees product quality but also increases the responsiveness of our service, thereby improving customer satisfaction and our organization's operational efficiency.

Discover our SAP training

We have our Master in Financial Management and Functional Consulting SAP S/4HANA Finance, Official Sap S/4Hana Sourcing And Procurement Certificate and Sap S/4Hana Finance Official Certificate.