In SAP MM (Materials Management), reservations are documents that enable planning and also ensure the availability of materials for future use.

In recent implementations, they are rarely used, but their knowledge is essential as they can be useful for internal business planning.

We show details on how reservations work:

Objective of the Reservations in SAP

- Reservations are created to have materials ready at a later date and for a specific purpose.

- They simplify and speed up the merchandise entry process.

- Different departments can request reservations for different goods issued related to various account assignment objects, such as cost centers, work orders, fixed assets, etc.

Information in one Reservations in SAP

A reservation stores important information for goods issue and subsequent requirements planning:

- What?: What material is needed.

- How much?: The required quantity of each commodity.

- When?: The date of need.

- Where from?: The center or warehouse of origin.

- Where to?: The recipient or customer.

A booking document consists of a header and at least one item. As with most SAP documents, we structure documents by the header, which contains general data, while each item describes the individual planned transactions.

Reserve Level in SAP

- Reservations can be made at the center level or at the warehouse level.

- For materials with batches, reservations can also be created at the batch level.

Manual and Automatic Reservations:

- Manual: The user creates reservations directly in the system.

- Automatic:

- Reservations for Orders, Networks, and WBS Elements: When you create an order, network, or project, warehouse components are automatically reserved.

- Transfer Reservations: If the available stock is below the reorder point, the system generates a transfer reservation in the plant for the replenishment quantity.

Effects of Introducing a Reservation:

- The system creates a reservation document as proof of the order.

- The total stock and the unrestricted stock of the material remain intact.

- The reserved stock is increased by the reserved quantity1.

- In short, reservations in SAP MM are essential tools for planning and ensuring material availability, optimizing incoming and outgoing goods processes.

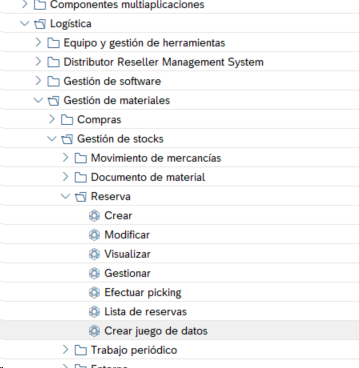

The most common transactions in SAP GUI are the following:

MB21 – Create Reservations in SAP:

Use transaction MB21 to create a new reservation manually.

Enter the details of each material here, including the quantity required, the date needed, and other relevant parameters.

This transaction will allow you to generate a specific reservation for a specific purpose.

MB22 – Modify Reservations in SAP:

Transaction MB22 allows you to modify existing reservations for materials.

You can adjust the quantity, date needed, or other attributes as needed.

MB23 – View Reservations in SAP:

With transaction MB23, you can view the details of a previously created reservation.

Provides information about the material, the reserved quantity, and other relevant data.

MB25 – Transfer Reservations in SAP:

Transaction MB25 is used to create transfer reservations.

If the available stock is below the reorder point, the system automatically generates a transfer reservation for the replenishment quantity.

MBVR – Cancel Reservations in SAP:

If you need to cancel a created reservation, you can use transaction MBVR.

Please ensure you provide the correct reservation number to cancel.

Discover our SAP training

Find out everything on our blog and train in SAP with our Master in Financial Management and Functional Consulting SAP S/4HANA Finance, Official Sap S/4Hana Sourcing And Procurement Certificate and Sap S/4Hana Finance Official Certificate.