You can place automated orders in SAP, optimizing and streamlining your organization's work thanks to the tips we provide in this post.

Every company or organization is unique, and each knows how to best manage its different workflows. Some organizations share purchase requisition departments with their purchasing department. Even if they come in through different channels, we can maintain approval workflows, and when you return to your daily work, you can verify the request and transform it into an order.

When these cases occur, or simply because we have so few purchase orders or materials that we don't care who to buy them from because they are residual in our organization, we assign a specific source of supply and transform it into an order.

SAP, being a German-origin program, offers practical tips for simplifying processes, eliminating unnecessary steps, and improving organizational efficiency.

Many SAP customers have MRP enabled and need to automatic way to place the order of purchasing materials that are missing from your warehouse or stock. Because SAP transactions are often processed by users only step by step, without making any changes, they do not add value to the respective process step.

After the MRP is executed or launched, orders can be automatically created in SAP and, if necessary, shipped without user intervention. (Savings in personnel entering orders)

Prerequisites Master data:

“Automatic Order” number in material and supplier:

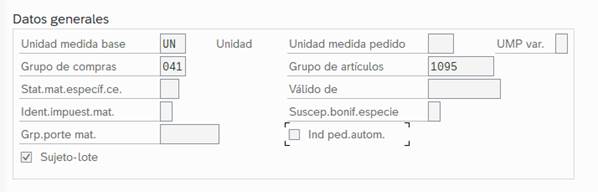

We access our material in the database and in the Purchasing tab in the center we specified, we go to General Data and we have to have the Automatic Order indicator pressed.

We enter transaction MM01 and save the material with the selected indicator.

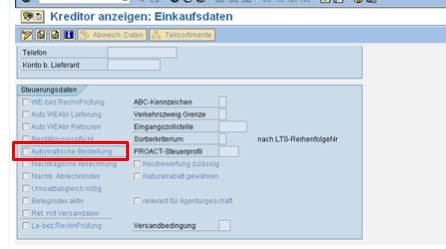

In the master record of the vendor from whom the material is ordered, the "Automatic order" indicator must be set in the purchasing data control data.

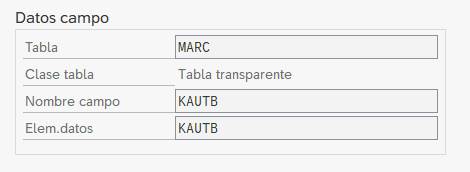

If we want to filter a table to find out which materials have an automatic order indicator, we can do so in the field name:

Another factor to consider for automatic ordering is the supplier.

Within the BP transaction we have to indicate that automatic ordering is allowed.

Finally, we access the automatic supply source so that it can be linked to the order request: (this topic has been discussed in another blog article)

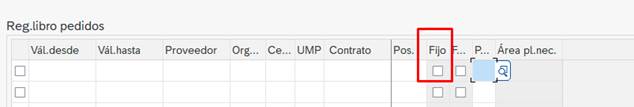

Update Source Determination – Order Book Entry

Define the source of supply by creating an automatic order book in SAP (transaction ME01) or by maintaining information records (transaction ME11).

Assign an automatic purchase order book in SAP to a material-vendor combination or create information records for a material-vendor combination.

Now we can perform two exercises: first, have an updated supplier so that it can be purchased with that material and make a purchase request. If it doesn't have Workflow, the order will be created automatically.

Another example is the launch of the MRP for that supplier/material, and the purchase requisition is created and converted to an automatic order. All this information can be found in the order history, which we can browse through its documents.

With this configuration in place, we can skip a step for the end user, doing it automatically, and as a control, we can run an automatic order workflow in SAP purchasing, without having to enter anything into requests, thus eliminating the workload for the end user.

Discover our SAP training

Find out everything on our blog and train in SAP with our Sap S/4Hana Finance Official Certificate.